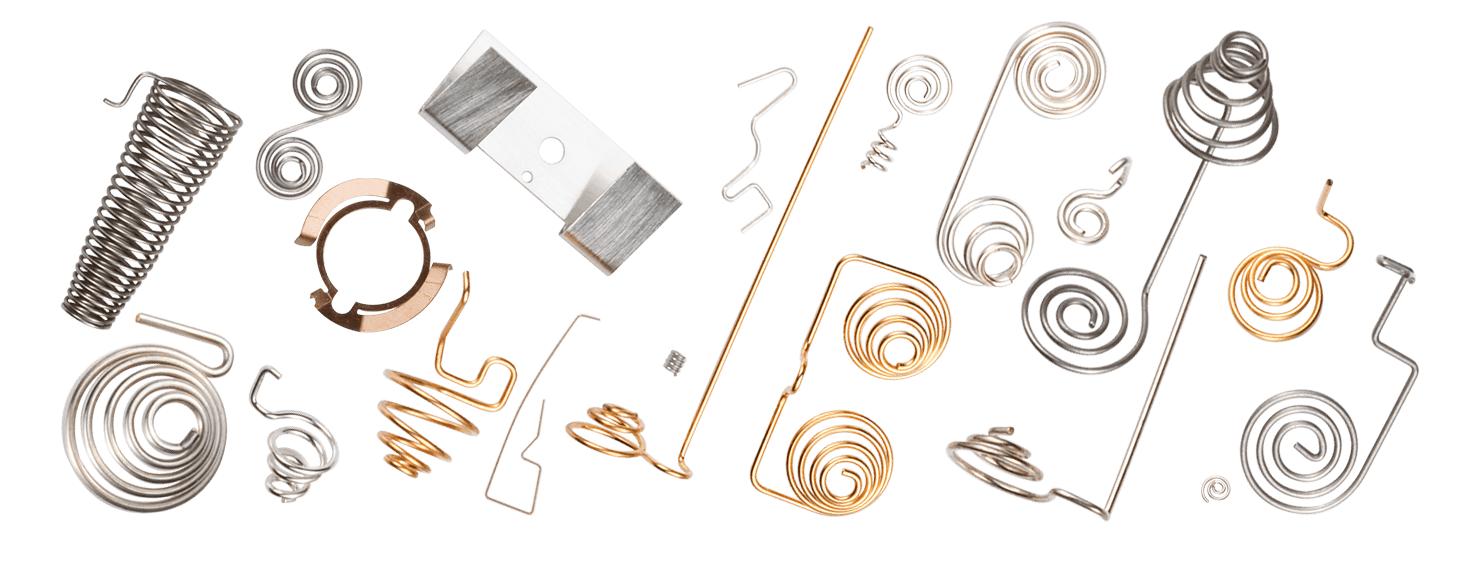

Battery Springs & Contacts

As a custom manufacturer of battery contacts and battery contact springs, Newcomb Spring can produce components in a virtually unlimited variety of shapes, configurations and designs. Our design assistance team can work with you to assess the manufacturing and performance considerations, as well as advise on the most cost effective process to ensure efficiency.

Spring design overview

A battery contact spring typically must perform two roles - to help provide pressure to hold batteries in place as well as to conduct electrical current from the batteries to the desired circuit. The force exerted by the spring on the battery or batteries often affects the electrical conductivity, especially where surface oxidation on the battery contacts may be present. Corrosion and oxidation, as well as the battery spring's suitability for specific soldering processes, should be considered during design.

Newcomb Spring will work with you to create an effective battery contact design for your application. With state-of-the-art equipment, a highly skilled team of spring-makers and our vast specialty material capabilities, our design assistance services can help save you time and cost on your battery springs and battery contacts.

Spring Materials

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- Beryllium Copper

- Phosphor Bronze

- Spring Brass

- Stainless Steel, Type 302, Type 316 & 17-7

- Music Wire, Nickel Coated

- Customer Specified

Spring Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Battery contact material conductivity

Generally, materials with higher mechanical properties have lower electrical conductivity. Often they are used for battery contact manufacturing where cost is a major consideration and where the needed conductivity can be achieved with a pre-plated carbon steel, such as music wire, nickel coated or with a subsequent plating process. When high conductivity is required, as in military weapon applications and computers, the designer will want to consider battery contact materials with higher copper content, such as beryllium copper, phosphor bronze or spring brass. In certain applications, battery contacts and battery springs are sometimes plated in tin, silver or gold plated-remove as a subsequent operation, which increases conductivity even more.

For more information, view our battery contact spring conductivity chart which shows the electrical resistivity and conductivity of materials most commonly used as battery contact springs.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us