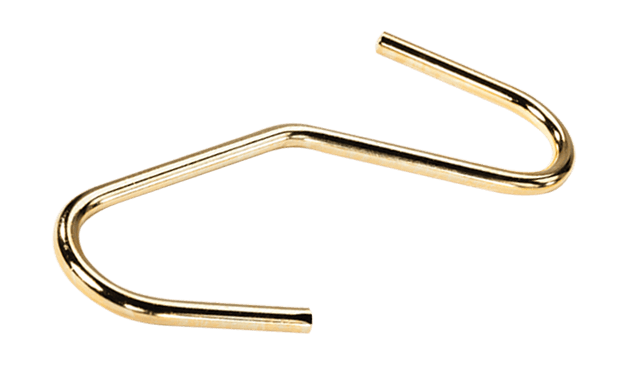

Hooks & Paint Hooks

Newcomb Spring paint hooks can be produced with a variety of ends types, all of which can vary in design based on your needs. As one of the industry's leading manufacturers of paint hooks, we recommend discussing your requirements with a Newcomb sales engineer who can verify manufacturing capabilities and will work to keep your production costs low.

Hook & Paint Hook Overview

Newcomb Spring does not stock hooks & paint hooks – all of our hooks are custom manufactured to exact customer specifications. Our design assistance experts can review your hook & paint hook design and offer suggestions to improve performance and lower costs. With high-speed forming equipment, including presses, 4-slides and CNC machines capable of bending wire up to 0.25 inches in diameter, our processes are designed for efficiency and help to lower costs and shorten turnaround times.

Hook Materials

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- Spring Steel & Carbon Steel

- Stainless Alloys

- Non-Ferrous Metals

- Elgiloy® & Hastelloy®

- Monel® & Iconel®

- Gold & Titanium

Shapes & Sizes

- .004 to .625 Inches In Spring Wire Diameter

- Up to 2.0 Inches Bar Stock

- Round, Rectangular, Square & Special-Section Wire

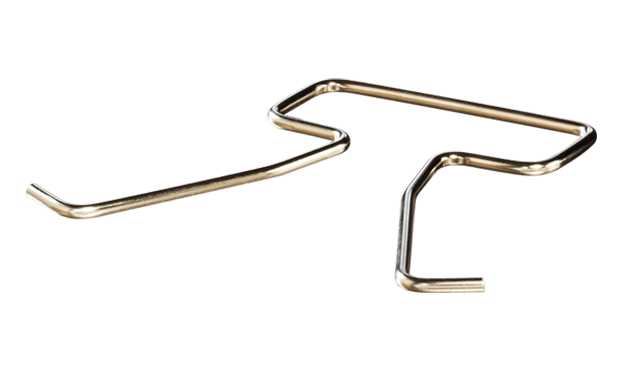

Hook & Paint Hook End Types

Most customers request V-shaped hook & paint hook ends. V-ends allow the part being painted to have two contact points, and the hook’s width, length and wire diameter can be adjusted per application requirements.

In addition to hooks & paint hooks, we also custom manufacture spring hooks. Spring hooks can stretch when loading and unloading, which provides significant costs savings in certain applications.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us