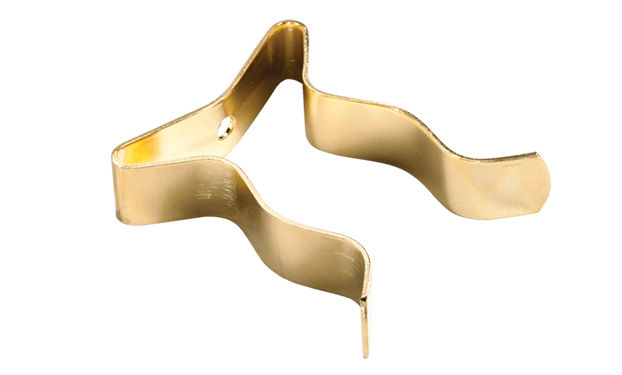

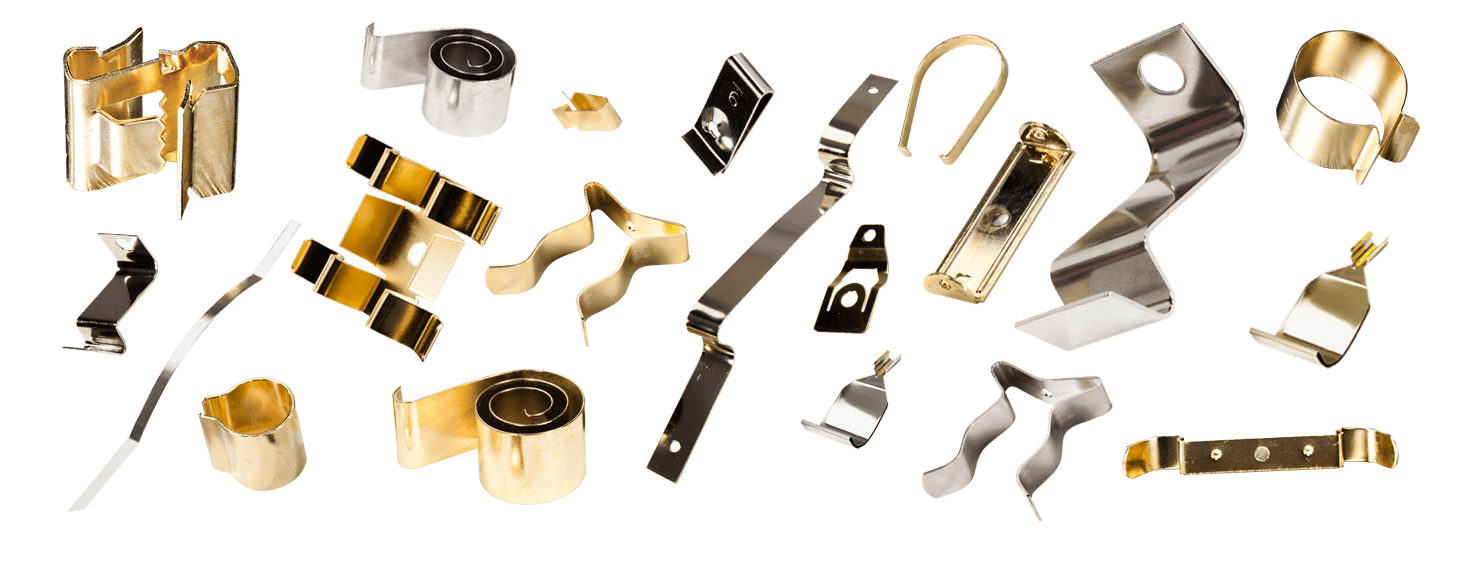

Flat Springs & Metal Stampings

As a custom flat spring manufacturer, Newcomb Spring can produce flat spring components in shapes, sizes and designs to meet your unique specifications. Using materials from .007 to .315 inches in wire diameter, we provide fast, accurate, and efficient spring services. We offer over a century of design and manufacturing experience, and can provide design assistance on your custom spring manufacturing order, working with you to help lower production costs and review your part's fit and function.

Spring design overview

Newcomb Spring is equipped to produce precision metal stampings and flat springs in small quantities from sheet material or etched blanks. For large, high-volume manufacturing runs, we typically utilize hard tooling. Newcomb often recommends that customers order a short run of stamping and flat spring parts to verify a component's functionality, thereby avoiding costly design errors.

The extensive variety of equipment we utilize to produce stampings, strip forms and flat springs, combined with our use of form tools, allows Newcomb Spring to create complex shapes as well as produce die sets that can be used for cutting, etching, extruding, notching, swedging, stamping and more. Our facilities also offer primary and secondary operation departments, which work to produce short-order flat form components of short-order flat forms.

Spring Design

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- Spring Steel & Carbon Steel

- Stainless Alloys

- Non-Ferrous Metals

- Elgiloy® & Hastelloy®

- Monel® & Iconel®

- Gold & Titanium

Spring Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Material considerations

Newcomb Spring is capable of manufacturing parts using virtually any material, although we typically produce flat springs and metal stampings from continuous coil material. The most frequently chosen coil materials are #3 slit edge, #5 deburred edge and #1 round edge. The main differences among these options are:

- #3 slit edge often is used when a die cut eliminates the edge of the material; when edge condition is not critical to a part's fit, form or function; or when costs prohibit other edge options.

- #5 deburred edge often is used when the edge condition is critical to a part's fit, form or function. This edging option offers improved safety in part- and stock-handling, as the edging process produces broken corners instead of square corners.

- #1 round edge is one of the safest material options in terms of handling parts and stock. This edging also increases the cycle life of torsion springs and leaf springs.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us