Extension Springs

Since it became First in Forming, Newcomb Spring has manufactured custom extension springs for customers around the world. We are one of North America’s largest and most experience extension spring suppliers, with a network of eight locations to better serve customers. Our spring engineers, manufacturing personal personnel and customer support staff are always available to assist, and design assistance is available on any extension springs order.

Spring design overview

Extension springs store energy and exert a pulling force. Usually, they are made from round wire and are close-wound with initial tension. Typical applications include tape cassette players, balance scales, toys, garage doors, automatic washing machines and various types of spring tensioning devices.

Extension springs are stressed tin torsion in the body. Design procedures for the body are similar to those discussed previously for compression springs with the following major exceptions. Most extension springs are coiled with initial tension, equal to the minimum force required to separate adjacent coils. Extension springs do not normally have set removed. Furthermore, unlike compression springs, extension springs do not have a solid stop to prevent overloading. For these reasons, design stress levels are generally lower for extension than for compression springs.

Spring Capabilities

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- .007 to .625 Inches In Spring Wire Diameter

- Up to 2.0 Inches Bar Stock

- Round, Rectangular, Square & Special-Section Wire

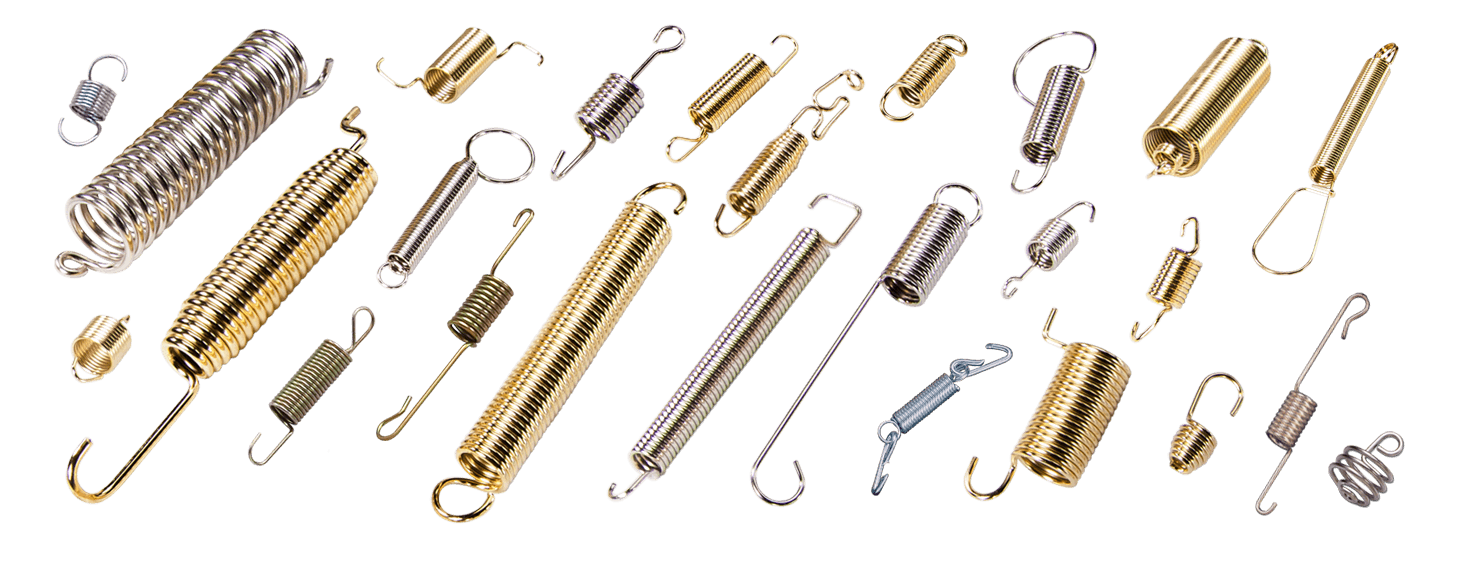

- Standard & Custom Extension Spring Body Shapes

Spring Manufacturing

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

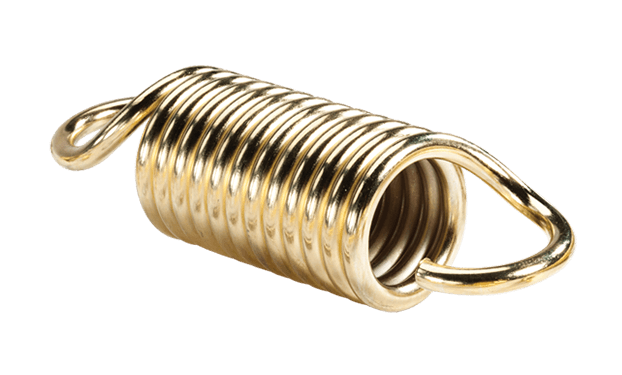

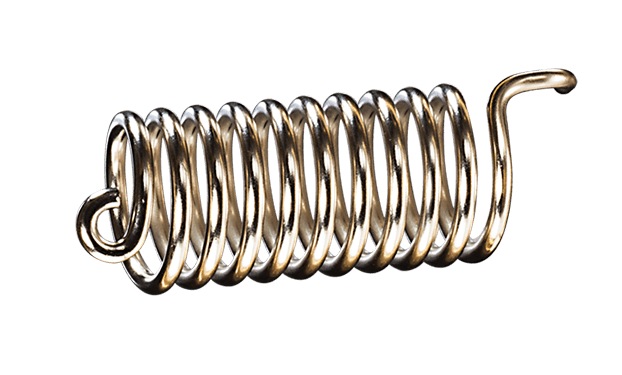

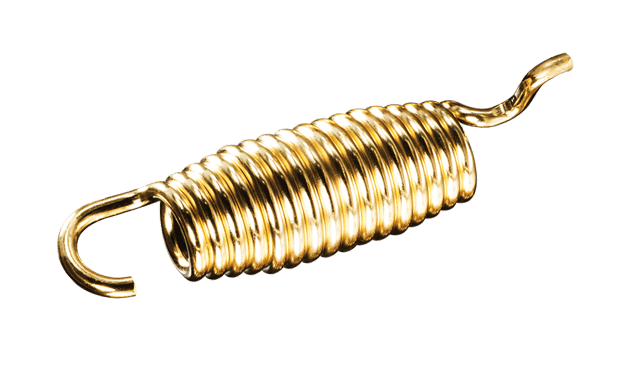

Extension Spring Ends

Extension springs require a method of attachment to other parts in an assembly. A wide variety of ends have been developed and used to successfully for many years – for example, threaded inserts, swivel hooks, twist loops, side loops, cross-center loops and extended hooks. Loops are attachment ends that have small gaps, while hooks are loops with a large gap. In fact, the variety of ends is almost unlimited. The most common configurations are those that can be formed during the spring making operation. Typical types include twist, cross center, side loops and extended hooks. Many of these configurations are made by bending the last coils of an extension spring to form loops. Most special hooks are formed from straight sections of wire on the so-called "tangent ends" of an extension spring body.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us