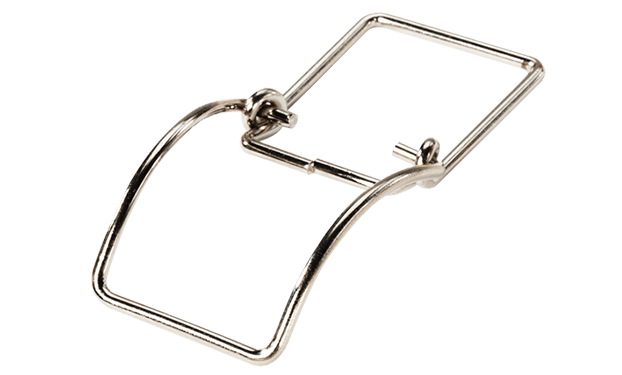

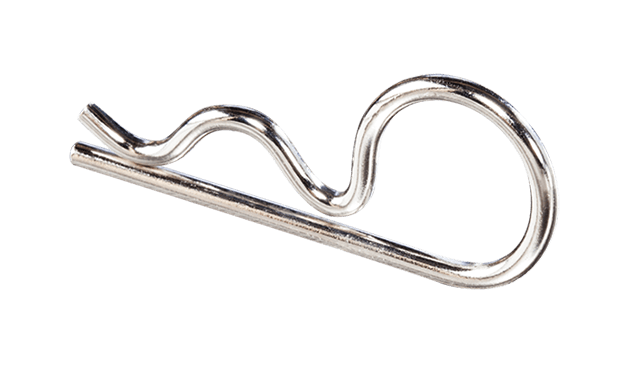

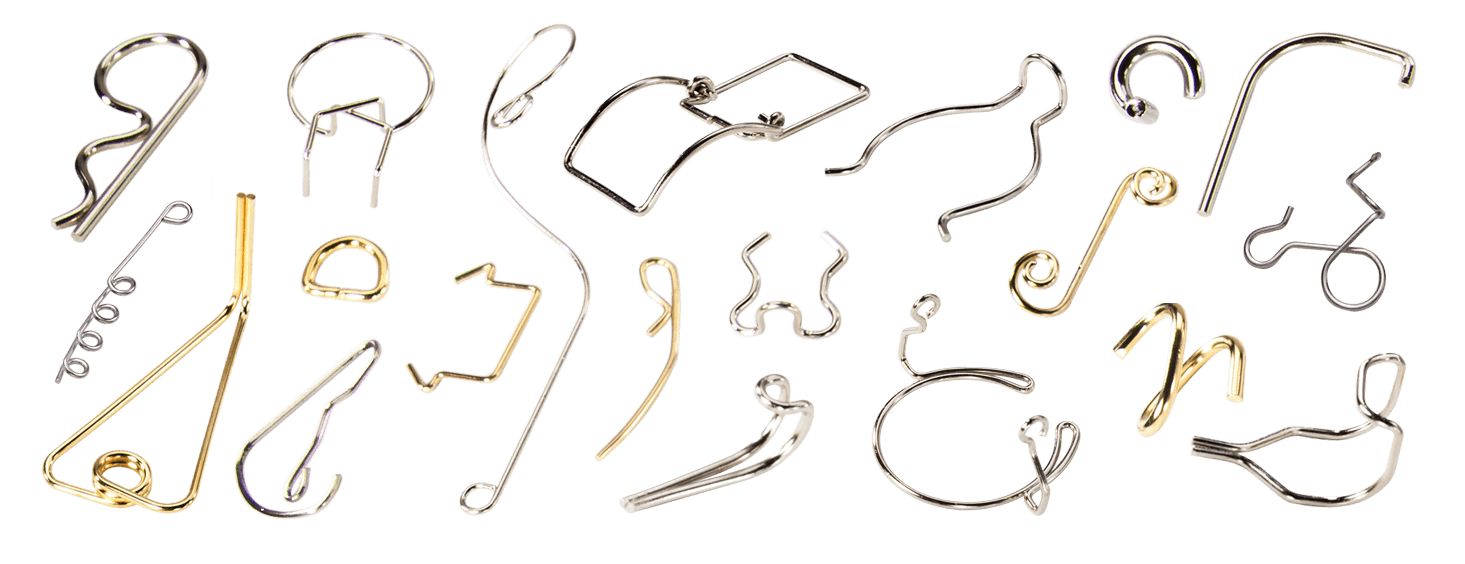

Wire Forms

As a custom torsion spring and double torsion spring manufacturer, Newcomb Spring can produce a wide variety of custom spring shapes, sizes and designs. Using material sizes from .007 to .625 inches in wire diameter, and up to 2.0 inches bar stock, all Newcomb parts are precision manufactured to meet even the strictest order requirements. With over a century of spring design and manufacturing experience we can provide design assistance on your compression spring order, helping lower production costs and review your part's fit and function.

Wire forms overview

Recent advances in CNC manufacturing technology have significantly lowered the cost of creating prototypes of complex wire form parts. The Newcomb engineering staff gladly assists customers with part design, and we often produce wire form prototypes to help make sure components will fit spatial requirements. Modern prototypes often can be changed and reproduced in minutes, saving time, lowering costs and avoiding design errors.

To make sure a component's dimensions fall within predetermined tolerances, wire forms often are stress-relieved during production. This process improves the reliability of Newcomb Spring wire forms in your products while streamlining the manufacturing process and lowering total production costs. The customer should also review proper bend radii considerations to ensure part performance and longevity.

Wire Form Design

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- Spring Steel & Carbon Steel

- Stainless Alloys

- Non-Ferrous Metals

- Elgiloy® & Hastelloy®

- Monel® & Iconel®

- Gold & Titanium

Wire Form Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us