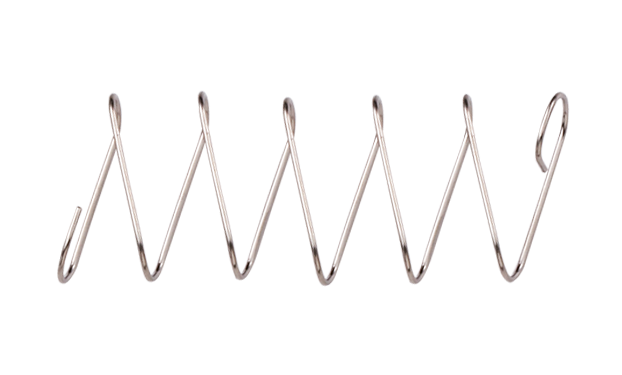

Magazine Springs

As a custom spring manufacturer, Newcomb Spring can produce magazine springs to meet your specific requirements. Due to the nature of many magazine spring and magazine catch spring applications, orders often utilize a selection of our advanced capabilities, including design assistance, advanced quality controls, assembly and finishing.

Spring design overview

Newcomb Spring manufactures magazine springs, as well as magazine catch springs, for a variety of applications and for many mission critical functions. We produce magazine springs on high-speed equipment using the latest quality-control technologies. Our state-of-the-art operations allow us to rapidly produce custom magazine springs with strict compliance to specifications. We also offer advanced quality controls for orders with highly-exact requirements.

Magazine springs often function near the sold height, and understanding the requirements of how these springs function is critical in their production. Our experienced spring engineers can provide design assistance to advise on special considerations, functionality and to lower magazine spring manufacturing costs.

Spring Design

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a standard, semi-precious and precious materials. Customers in some of the world’s most precise industries rely on Newcomb Spring to product parts using:

- Spring Steel & Carbon Steel

- Stainless Alloys

- Non-Ferrous Metals

- Elgiloy® & Hastelloy®

- Chrome Vanadium & Iconel®

- Chrome Silicon & Titanium

Many customers request magazine springs manufactured using 17-7 stainless steel, though we are also able to utilize a wide variety of standard and specialty materials. Many of our magazine springs undergo secondary processes, such as heat-treating or stress relieving, to improve part lifespan and performance.

Spring Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us