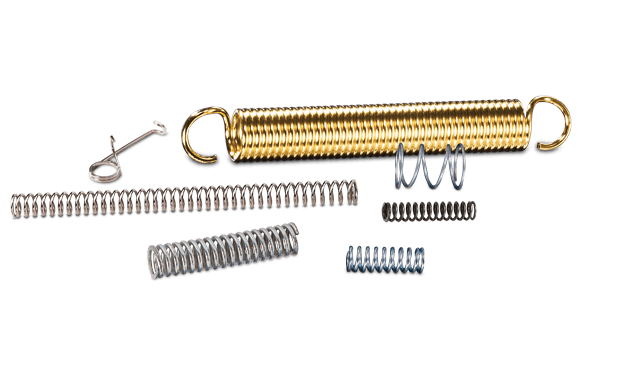

Micro Springs

Newcomb Spring manufactures micro compression spring, extension spring and torsion spring components in a variety of shapes, lengths and materials. All of our parts are custom produced to meet your specifications and needs. We maintain the strictest compliance to order specifications for all micro spring parts, producing precise components for even the most critical applications. Many of our micro springs are utilized in medical applications, however, with our extremely strict compliance to specifications, Newcomb micro springs and micro-sized components are used by a variety of industries and in specialized functions.

Spring design overview

All of our micro springs are available in varying lengths, in standard and custom spring body designs. As a manufacturer of completely custom micro spring components, Newcomb can produce parts to meet your needs and application. We offer design assistance on all micro spring parts we produce, and even have our very own spring calculator, the Springulator®, to help customers in the engineering of their micro springs.

Spring Design

Newcomb Spring’s production consistency and accuracy is unrivaled. With low error and scrap rates, our operations maintain low costs and minimal waste, which allows us to cost-effectively provide parts out of a wide variety of a materials and sizes:

- .0015 to .006 inches in spring wire diameter

- Micro compression, extension & torsion springs

- Standard & custom micro spring body shapes

- Often used for medical applications

- Custom micro springs, manufactured to your specifications

Spring Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us