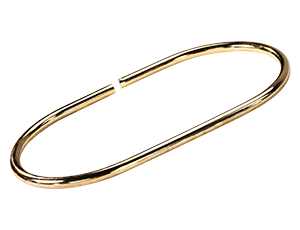

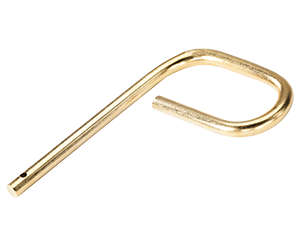

Large Wire Bending

Newcomb Spring brings the same CNC technology, manufacturing expertise, and quality control offered in our custom spring and metal forming operations to large wire bending. Whether you require long production runs, or short, Newcomb Spring is ready to meet your needs with wire bending services that support the quality and performance that exceed your expectations for excellence.

Wire bending overview

Our state-of-the-art CNC wire bending machinery delivers precise metal bending without deflection or sagging, with repeatable geometries that match your specifications. Plus, our advanced measurement and proven quality assurance systems are available to keep production runs accurate from start to finish.

Markets and Products

Newcomb Spring’s wire bending services are ready to address your needs in markets such as:

- Transportation — Automotive seat structures, wire frames for sun shields and headrests, hood (bonnet) stays, custom brackets, headliner supports, and more

- Kitchen and Bath — Custom wire frames for shower caddies, storage solutions, roll holders, and wire baskets

- Rack Mounting — Frames, hooks and brackets

- Furniture — Custom wire frames for chairs, storage units, handles, and hanging systems

- Retail Shop Fittings and Merchandise Displays — Wire frames for shopping carts, frames and handles for wire baskets, literature and card racks, blister hooks, and more

- Appliances and Housewares — Oven and dishwasher racks, refrigerator shelving, hooks, racks, wireframe shelves and home storage solutions

- Medical and Veterinary — Wire tray and wire instrument basket frames, infusion hooks, handles, brackets, wire frames for animal cages, and more

Prototyping Services

Maintaining quality, controlling production costs, and being sure the parts we manufacture are optimally suited to your application is what drives us. Our engineering and production teams are ready to assist in the manufacturing of prototypes to produce parts that best fit the form and function of your application. With CNC technology, prototypes often can be changed and reproduced in minutes. Prototyping and careful pre-production evaluation saves time, minimizes waste, lowers costs, and helps avoid design errors.

Spring Capabilities

Newcomb Spring produces spring, wire form and metal stamped parts out of virtually any material. Often our metal parts are manufactured using stainless spring steel, though we offer a full line of material options, and can custom manufacture your part using virtually any material you require. We use continuous coil as well as strip materials, and our common material shapes include spring steel, high carbon steel, low carbon steel, nickel plated carbon steel, stainless alloys, non-ferrous metals, Elgiloy®, Hastelloy®, and more.

Our process

We work to continuously adapt to the ever-changing needs of the metal form and spring manufacturer market, and consistently invest in new production technologies and machinery. Newcomb Spring offers a network of facilities that allow us to respond locally and act globally. We are proud of our position as one of North America's most respected and largest metal form and spring manufacturers, and work hard every day to deliver the highest quality, custom manufactured springs and metal forms.

About us